Introduction

The Vibration Detection CAD Tool is specialized engineering software designed to process and analyze subtle mechanical oscillations in MEMS devices and micro-scale systems through advanced digital signal processing (DSP). This tool captures and visualizes vibrations that conventional methods often miss, making it an essential solution for laboratories and industrial applications where precision at the nanometer scale is critical.

Core Features of the Vibration Detection Tool

Advanced Signal Processing for Vibration Detection Tool

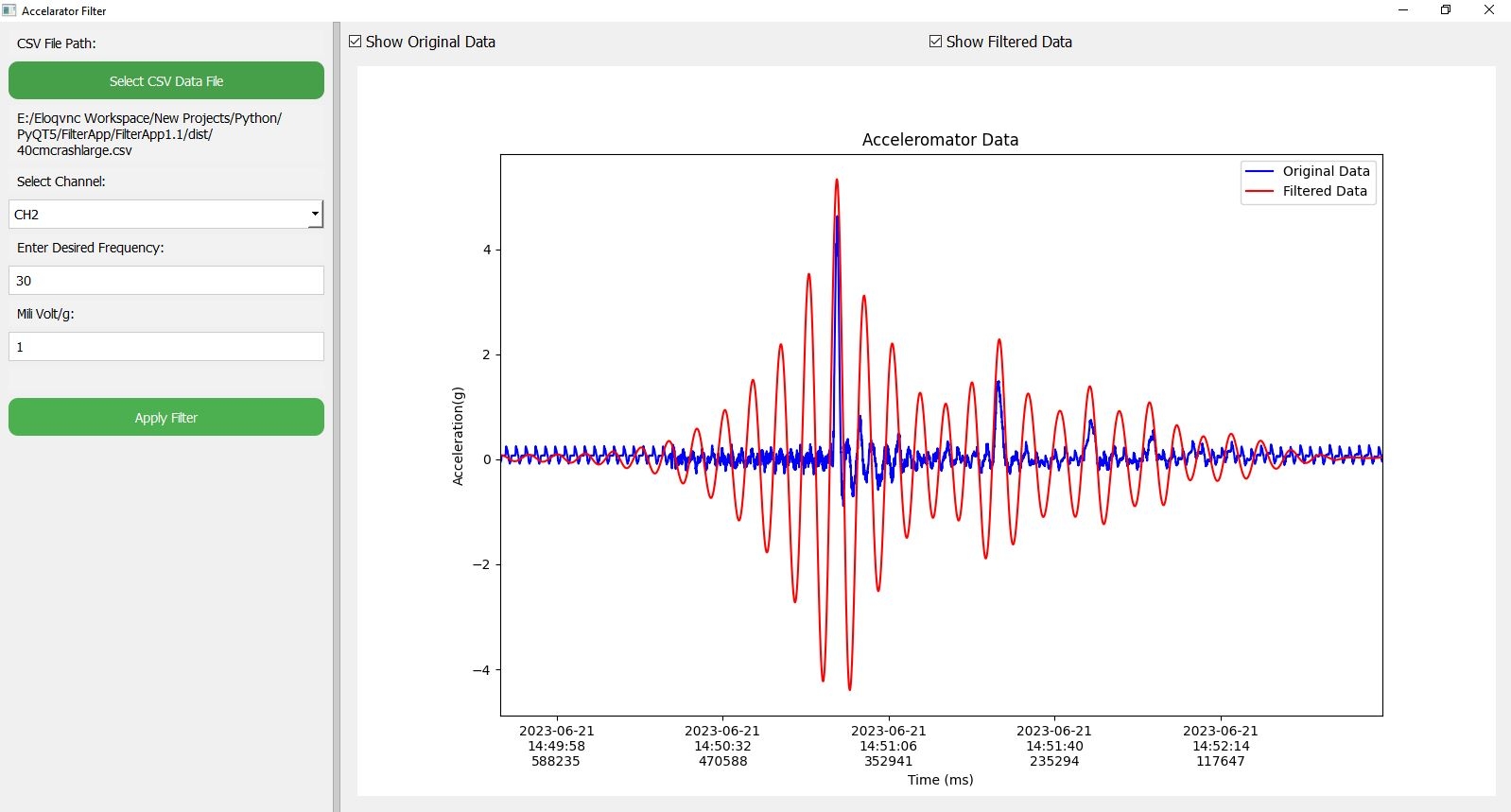

The Vibration Detection CAD Tool leverages sophisticated DSP algorithms for real-time filtering, FFT-based frequency analysis, and noise reduction. It allows users to import multi-channel data from accelerometers and piezoelectric sensors, applying custom digital filters to isolate specific frequency bands. The software’s zoom functionality reveals microsecond-level variations, providing the resolution needed for detecting minute vibration signatures in sensitive equipment like scanning electron microscopes, optical assemblies, and precision manufacturing systems.

Data Visualization in the Vibration CAD Tool

Transform complex vibration datasets into actionable insights through an intuitive dashboard featuring synchronized time-domain plots, power spectral density graphs, and waterfall displays. The tool generates comprehensive statistical summaries including RMS values, peak amplitudes, and kurtosis indicators. Automated reporting exports results in PDF, CSV, and industry-standard formats, streamlining documentation for compliance, research publications, and predictive maintenance planning.

Integration & Engineering Workflow

Designed for seamless integration into existing engineering ecosystems, the software supports common data formats from industry-standard hardware including National Instruments DAQ systems, Bruel & Kjaer analyzers, and IoT vibration sensors. The tool’s API enables automated data pipelines between measurement hardware and enterprise systems like PLM and CMMS platforms. This interoperability ensures minimal disruption to established workflows while adding sophisticated analysis capabilities to routine monitoring procedures.

Applications for Micro-Scale Vibration Monitoring

This specialized tool serves critical functions across multiple sectors:

MEMS/NEMS Development: Characterizing dynamic responses and validating finite element models of micro-scale components

Precision Instrumentation: Monitoring and mitigating environmental vibrations in semiconductor fabrication tools, atomic force microscopes, and optical benches

Aerospace & Defense: Analyzing vibration in miniaturized avionics, guidance systems, and satellite components

Medical Devices: Ensuring reliability in microfluidic systems, surgical robotics, and implantable sensor arrays

Automotive Electronics: Testing vibration resilience in miniaturized control units and sensor packages

Customization and Technical Support

We recognize that every application presents unique challenges. Our team provides rapid customization for specific sensor protocols, proprietary data formats, and specialized analysis algorithms. Advanced implementations can incorporate machine learning modules for anomaly detection and predictive failure analysis. Comprehensive technical support includes 24/7 access to engineering expertise, detailed documentation libraries, and regular software updates incorporating the latest DSP methodologies.

Learn more about CAD technologies: PTC CAD Solutions

Deepen your DSP knowledge: Developing Software for Digital Signal Processing

Explore our other engineering tools: CAPSOFT: Computer Aided Programs and Software

Core Features

Source & Tools

Fiverr, Visual Studio, GitHub

Frontend & Backend

Python PyQT5, CSS

Features & Functionalities

NumPy, SciPy, MatlotLib, PDF Export, Digital Signal Processing, Filter Design